Manufacturing Capabilities

100% In-house production under one roof. This helps us to have full control over quality and meeting delivery schedules.

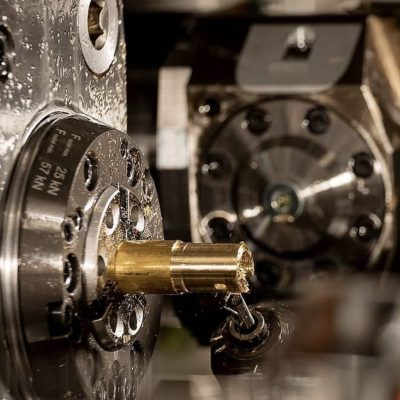

- Sliding Head CNC machines with twin spindle and bar feeders

- Turn-Mill machining centres with Y axis and sub spindle

- Vertical milling Machines and SPM machines

- Hot Forging Press and machining

- Single and Multi spindle automatic lath machines

- 8 station rotatory table machines

Surface Finish

Nickel, Tin, Chrome, Zinc, Copper, Sandblasting, Pickling etc..

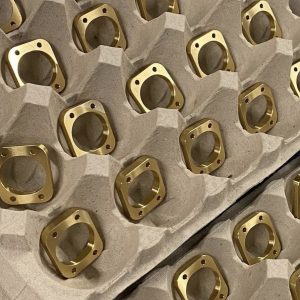

Customised Packing

Bar Coding, Labelling, 100% batch tracing of lots, Kit Packings, Euro Pallets

Cost Reduction

Shorter Cycle times and Faster delivery. Highest Industry Standards.

Zero Defects

We strive to achieve Zero defects in our parts supplied.

Timely Delivery

We are committed to our promise of delivery time and meeting targets.

VMI

Managing Vendor Inventory, Inventory audits and ready to ship material.

IMDS Entry, PPAP Level 3, SPC, Cpk, Control Plans and much more.

Peace of mind comes when right quality is delivered on right time.

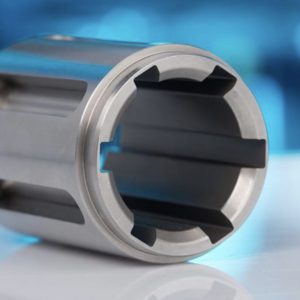

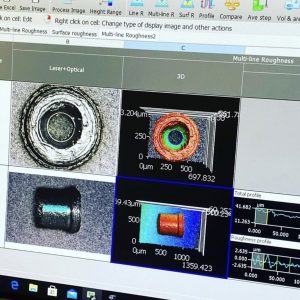

Quality is in details ...

We combine cutting-edge technology, innovative solutions, and experienced teams to help bring some of the finest quality parts.

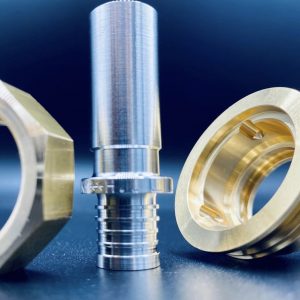

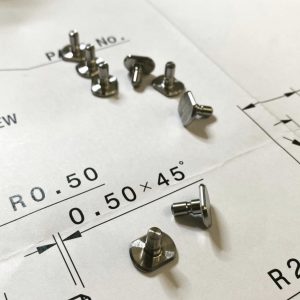

Precision Machined Components

At BRASSLAND, we have multi-axis machines that are capable of manufacturing workpieces to turned, cross-drilled, milled, and engraved in one machine. The tolerance can be achieved as ± 0.01mm, our versatile multi-tool 3,4,5 axis CNC machining allows us to make parts as small as 2.00 mm in diameter. Our CNC machining centers enable us to offer custom and integrated solutions that can help you shorten production time and reduce machining costs

Design Assistance

Helping our customers during the design phase of a project. We find it key to the success of a product launch to be involved early in the design. Our design assistance reduces not only lead time by avoiding unnecessary iterations but will also substantially reduce cost.

Shorter Lead Times

We help customers fulfill critical supply chain needs quickly. Fast turnaround times are achieved through a dedicated workforce working within a fully integrated manufacturing environment.

Integrated Manufacturing

We have gone to great lengths to perform as much of the production process within our own facility. This major advantage reduces the frequency of quality issues which in turn help ensure that we meet delivery deadlines faithfully.

Why Brassland ?

- Innovation : We are consistently developing new solutions to complex manufacturing problems.

- Mordern Manufacturing Facility : Sliding head CNC Machines.

- Quality culture : Our long track record of conformance and acceptance speaks for itself.

- Responsive & dependable : We are large enough to handle your supply chain needs and flexible enough to respond to your requests quickly.